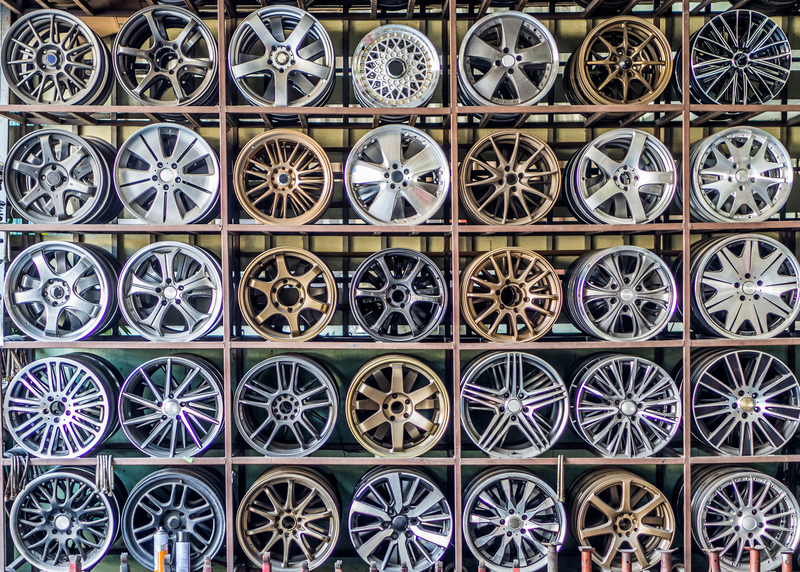

The Differences Between Diamond Cut and Powder Coated Alloy Wheels

Currently, most vehicles have wheels that are made from either magnesium or aluminium, which are mixed with traces of additional metals to provide more strength. The powder-coated alloy wheels have been shown to give wheels a more durable finish whereas the diamond cut wheels have been found to have a high shine appearance that is commonly utilized by reputable brands to showcase their high-end models. Technically, some of the finishes may be combined. Most wheels, regardless of being powder coated or diamond cut, a lacquer is applied during the finishing phase to prevent corrosion.

Diamond-Cut wheels

Diamond-Cut wheels are initially painted in a specific colour and then an oven is used to bake them. After they have dried, the wheel is ultimately placed on the Computer Numerical Controlled Diamond Cutting Lathes to machine the face of the wheel so to get a metallic diamond-cut finish.

It is also important to take note of the fact that the diamond-cut finish is still prone to damage even though it has been lacquered. Furthermore, it is not always possible to continually re-cut the diamond cut wheels every time they are marked or chipped. This is because some of the metal could be removed and over time this will negatively affect the wheels structural integrity. The safest way to extend their lifecycle is by cleaning them using pH neutral cleaners or mild car shampoo.

Powder Coated

Powder coating is usually applied in the form of a dry powder. The main difference between powder cut alloys and diamond-cut alloys are the fact that powder coating does not need any solvent. A coating is electrostatically applied using powder coating equipment and cured using heat to enable it to flow and create a long-lasting ‘skin’. This is the process that forms a hard finish which is more durable than conventional paint. However, powder-coated alloy wheels are lacquered the same way as paint refurbish.

The Processes

The look of diamond cut alloys comes with a finish which is higher in shine and resembles a DVD finish. Whereas it is the fine grooves that give a DVD a higher shiny finish, smaller grooves have a similar effect on the alloy wheels. This can, without doubt, attract you to a car in the showroom with reduced effort because they are outstanding since they have a great aesthetic look, which could be difficult to beat.

Preparation Processes

As a phase of the finishing procedure, machine diamond cutting Lathes are used for cutting an additional edge in the alloy. This is what forms a faint grooved effect which eventually creates the high shine finish. This results in perfectly machined alloy wheels that are less costly as compared to powder cut alloys. Utilizing the customers desired colour choice, a specialist powder coating equipment is used to apply the paint. The wheel is then placed in an oven for a specified temperature and time prior to the application of a clear coat.

Most modern cars possess a key component in either powder-coated alloy or diamond-cut alloy wheels. The look of a new car can be perfectly set off with the ideal set of wheels, nonetheless, most customers fail to understand the main difference between powder cut and diamond-cut alloy wheels.

If you find any of the information presented here useful then you might enjoy our other blogs. Additionally, you can contact us or call us on 01604 600581.